Implementing effective sectioning procedures in automotive repair is crucial for enhancing sustainability, reducing environmental impact, and minimizing energy consumption. By separating and categorizing materials from damaged vehicles, car collision and Mercedes Benz repair sectors can foster a circular economy, choosing eco-friendly alternatives like water-based paints, and adopting advanced technologies to minimize waste and lower rework costs. These optimized sectioning procedures lead to greener practices, cost savings, and enhanced productivity across industries.

In today’s world, understanding and implementing efficient sectioning procedures is a cornerstone of sustainable practices. This article explores how these procedures, when thoughtfully executed, can significantly reduce an operation’s environmental impact. We delve into crucial aspects such as material selection, considering the ecosystem and optimizing work methods to foster a greener future. By examining these strategies, businesses can navigate towards more eco-friendly practices while enhancing operational efficiency.

- Understanding Sectioning Procedures: A Foundation for Sustainability

- Environmental Considerations in Material Selection

- Optimizing Practices for Reduced Impact and Increased Efficiency

Understanding Sectioning Procedures: A Foundation for Sustainability

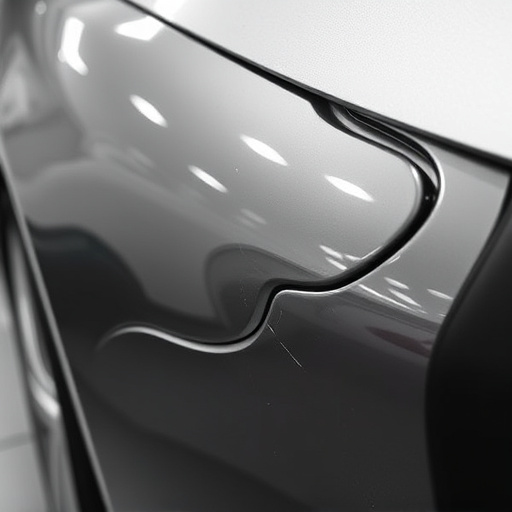

Understanding sectioning procedures is paramount in modern automotive industry efforts to enhance sustainability. This meticulous process involves carefully separating and categorizing materials from damaged vehicles, such as metal, plastic, glass, and electronics. By doing so, we move away from traditional waste management methods that often contribute to environmental degradation. In essence, it’s a foundational step towards greener practices within the car collision repair and mercedes benz repair sectors, fostering a circular economy where resources are reclaimed and reused.

Effective sectioning procedures play a pivotal role in minimizing the ecological footprint of car body repair. It enables the efficient recovery of reusable components, reducing the demand for new raw materials. Moreover, it diminishes energy consumption and greenhouse gas emissions associated with manufacturing processes. When implemented correctly, these practices not only contribute to cost savings but also ensure that discarded vehicles become valuable resources for future applications, echoing a broader trend in the automotive industry to revolutionize waste management through sustainable initiatives.

Environmental Considerations in Material Selection

When implementing sectioning procedures, especially in industrial settings like a car repair shop, environmental considerations play a pivotal role in material selection. The choice of materials used in auto painting and car paint repair processes directly impacts air quality, water usage, and waste generation. Eco-friendly alternatives are increasingly favored to minimize these environmental effects. For instance, water-based paints and solvents are preferred over volatile organic compounds (VOCs) to reduce air pollution and greenhouse gas emissions.

In the context of sectioning procedures, selecting materials that facilitate efficient and sustainable car paint repair can significantly contribute to a greener environment. Proper disposal methods and recycling programs also play a crucial role in reducing the environmental impact. Thus, by being mindful of these considerations, auto painting processes can be more harmonious with nature, ensuring both high-quality repairs and a healthier planet.

Optimizing Practices for Reduced Impact and Increased Efficiency

In the realm of sectioning procedures, optimizing practices can significantly reduce environmental impact while enhancing overall efficiency. This involves adopting eco-friendly techniques and materials throughout the process, from initial planning to final disposal. For instance, utilizing advanced cutting technologies in auto body services can minimize material waste, a key aspect in car body restoration projects. By integrating sustainable solutions, such as recycled or biodegradable composites, businesses can contribute to a greener industry while maintaining high standards of quality.

Furthermore, streamlining workflows and implementing digital tools for design and simulation can help avoid costly mistakes and unnecessary rework, all while minimizing energy consumption. In the case of auto glass repair, for instance, leveraging precision engineering ensures that replacements fit perfectly, reducing the need for additional materials or modifications. These optimized procedures not only foster a more sustainable environment but also contribute to cost-effectiveness and improved productivity in various sectors, from automotive to construction.

By understanding and implementing efficient sectioning procedures, we can significantly reduce the environmental impact of our practices. This article has explored foundational knowledge on sectioning procedures and highlighted crucial aspects of material selection and practice optimization. Embracing these strategies fosters a more sustainable future, ensuring minimal ecological disruption while maximizing operational efficiency. Through conscious efforts to adopt eco-friendly approaches in sectioning, industries can contribute to a greener world without compromising productivity.