Mastering sectioning procedures is vital for accurate, efficient, and aesthetically pleasing auto body repairs and aftermarket parts installation. By dividing complex bodywork into manageable sections, technicians enhance precision, preserve structural integrity, and streamline Mercedes Benz and automotive collision repair processes. This involves deep vehicle design knowledge, careful planning, and precise execution, ensuring higher accuracy in alignment and seamless integration of new parts. Effective sectioning procedures are key to achieving high-quality car paint repairs and the longevity of aftermarket components.

Sectioning procedures play a pivotal role in streamlining aftermarket parts installation, ensuring precision and quality. This comprehensive guide delves into the intricate world of sectioning, highlighting its foundational importance. We explore how these procedures optimize the process, from enhancing efficiency to tightening quality control. By understanding best practices for effective sectioning, professionals can ensure seamless integration of aftermarket components, ultimately elevating the overall installation experience.

- Understanding Sectioning Procedures: A Foundation for Precise Aftermarket Parts Installation

- Benefits of Sectional Assembly: Enhancing Efficiency and Quality Control

- Best Practices for Effective Sectioning: Ensuring Seamless Integration of Aftermarket Parts

Understanding Sectioning Procedures: A Foundation for Precise Aftermarket Parts Installation

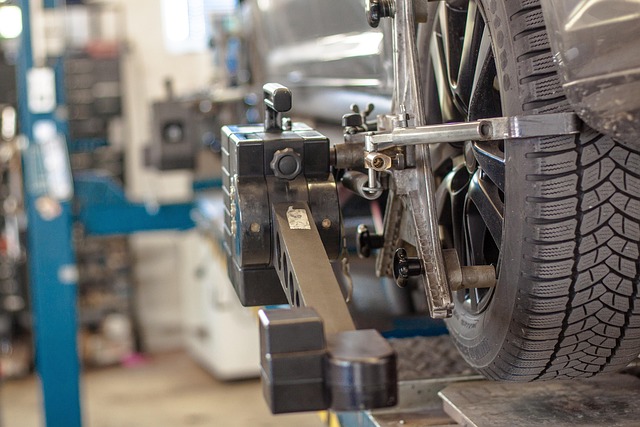

Understanding sectioning procedures is paramount for ensuring precise aftermarket parts installation, especially in auto body repair and vehicle paint repair scenarios. These meticulous processes involve breaking down complex car bodywork into manageable sections, allowing technicians to access and replace specific components with minimal disruption to surrounding areas. By sectioning off damaged or faulty parts, professionals can accurately measure and fit new aftermarket parts, maintaining the vehicle’s structural integrity and aesthetic appeal.

Mastering sectioning procedures demands a deep understanding of vehicle design and construction. Technicians must carefully plan and execute each step to prevent damage to adjacent panels or finishes during the removal process. Proper sectioning not only facilitates easier installation but also promotes higher accuracy in alignment, ensuring that aftermarket parts seamlessly blend into the existing car bodywork.

Benefits of Sectional Assembly: Enhancing Efficiency and Quality Control

The advent of sectioning procedures has brought about significant changes in how aftermarket parts are installed across various vehicle models, including Mercedes Benz repairs and automotive collision repair processes. One of the most notable benefits is the enhancement of efficiency. By breaking down a vehicle into sections during disassembly, technicians can more accurately locate and replace specific components, eliminating time-consuming searches throughout the entire car. This targeted approach expedites the repair process, reducing downtime for vehicle owners.

Moreover, sectioning procedures dramatically improve quality control. Isolating distinct parts allows for meticulous inspection, ensuring that each component meets the required standards before reassembly. This meticulousness is especially crucial in intricate vehicle restoration projects, where attention to detail can make all the difference between a mere repair and a masterpiece.

Best Practices for Effective Sectioning: Ensuring Seamless Integration of Aftermarket Parts

Effective sectioning procedures are essential for a successful aftermarket parts installation process. The best practices involve meticulous planning and execution to ensure seamless integration of new components into the vehicle’s existing system. First, thorough research is crucial; understanding the specific auto collision center requirements, including compatibility, dimensions, and potential modifications needed, guarantees accurate fitting. This step is vital in preventing costly mistakes during or after installation.

Additionally, precise measuring and marking techniques are employed to indicate cutting points and ensure proper alignment. Skilled technicians use these guidelines for clean cuts, facilitating the insertion of aftermarket parts while maintaining the vehicle’s structural integrity. Proper sectioning procedures not only enhance the overall quality of car paint repair but also contribute to the functionality and longevity of the modified components, making them a key consideration in any vehicle repair process.

Sectioning procedures play a pivotal role in streamlining aftermarket parts installation, offering a structured approach that enhances efficiency and ensures precision. By adopting best practices and understanding the benefits of sectional assembly, automotive professionals can achieve superior quality control and seamless integration of components. This focused strategy not only saves time but also guarantees optimal vehicle performance, making sectioning procedures an indispensable tool in the modern aftermarket landscape.