Sectioning procedures are crucial for efficient multi-shop auto repair coordination, enabling businesses to manage complex car body repairs and painting jobs effectively. By dividing tasks among specialized shops based on expertise, these procedures streamline workflows, maintain quality control, and reduce turnaround times. This structured approach enhances customer satisfaction by delivering high-quality, like-new car bodies through superior services and finishes. Implementation of standardized sectioning procedures across multiple repair centers offers significant benefits, but challenges such as technological adoption and information transfer require robust strategies including digital tools, training, clear responsibilities, and effective communication protocols to enhance the customer experience.

In the intricate world of multi-shop repair coordination, efficient sectioning procedures form the bedrock of successful collaboration. This article delves into the art and science of sectioning, exploring its pivotal role in streamlining complex repairs across diverse shops. From graspings the core concepts to uncovering best practices and addressing challenges, we provide an in-depth guide on optimizing sectioning techniques for enhanced coordination and improved outcomes. Unlock the secrets to effective multi-shop management through understanding and implementing robust sectioning procedures.

- Understanding Sectioning Procedures: The Foundation of Multi-Shop Repair Coordination

- Key Components of Effective Sectioning Techniques for Complex Repairs

- Best Practices and Common Challenges in Implementing Sectioned Workflows Across Multiple Shops

Understanding Sectioning Procedures: The Foundation of Multi-Shop Repair Coordination

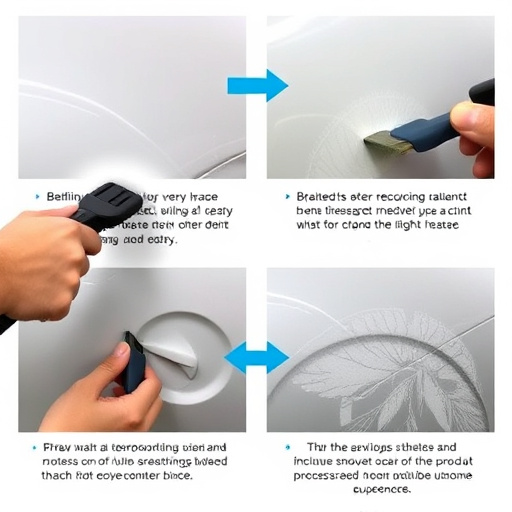

Understanding sectioning procedures is paramount to the success of multi-shop repair coordination. These procedures dictate how different aspects of a car body repair or auto painting job are divided and handled among various specialized shops. By streamlining this process, businesses can ensure efficiency, maintain quality control, and reduce turnaround times. Each shop focuses on its area of expertise, whether it’s intricate auto body services, complex car body repair, or precise auto painting, contributing to a comprehensive restoration.

Effective sectioning procedures serve as the backbone of coordinated efforts between these shops. They define clear roles and responsibilities, enabling seamless communication and collaboration. This structured approach minimizes errors, delays, and redundancies, ultimately enhancing customer satisfaction with the final product—a flawless, like-new car body that combines superior auto body services, expert car body repair, and exquisite auto painting.

Key Components of Effective Sectioning Techniques for Complex Repairs

Effective sectioning procedures are a cornerstone of successful multi-shop repair coordination, especially for complex automotive collision repairs. The key components involve meticulous planning and clear communication. First, defining the scope of work is crucial; breaking down the auto painting and fender repair into manageable sections allows for more accurate material estimation and efficient labor allocation. This involves creating detailed work orders that outline each step, from initial assessment to final quality control, ensuring every shop involved understands their specific role.

Second, leveraging technology for sectioning enhances coordination significantly. Digital platforms facilitate real-time updates, enabling teams to track progress seamlessly. Computer-aided design (CAD) software can be utilized to create precise layouts and specifications, streamlining the fender repair process. Additionally, cloud-based systems enable secure file sharing, ensuring everyone works from the latest project blueprints, which are essential for intricate auto collision repairs that require meticulous attention to detail.

Best Practices and Common Challenges in Implementing Sectioned Workflows Across Multiple Shops

Implementing sectioned workflows across multiple auto repair shops or collision repair centers presents both opportunities and challenges for efficient multi-shop repair coordination. Best practices involve standardizing procedures, leveraging digital tools for seamless communication and data exchange, and fostering a culture of collaboration among staff at different locations. Standardization ensures consistency in sectioning procedures, facilitating smoother hand-offs between shops for complex car body repairs or specialized services.

Common challenges include varying levels of technological adoption, resistance to change from established workflows, and ensuring accurate information transfer. Auto repair shop managers must invest in training and support to overcome these hurdles. Digital platforms that integrate with existing systems can enhance communication, streamline documentation, and reduce errors associated with manual data transfer. Additionally, clear lines of responsibility and effective communication protocols are vital for successful coordination, ensuring every stakeholder understands their role in the sectioning procedures for a seamless customer experience across multiple repair centers.

In conclusion, mastering sectioning procedures is paramount for seamless multi-shop repair coordination. By understanding the foundational concepts outlined in this article and implementing effective techniques, repair shops can streamline complex workflows, enhance efficiency, and deliver superior customer service. Embracing best practices and addressing common challenges will ensure successful integration of sectioned workflows across multiple locations, ultimately fostering a cohesive and productive repair ecosystem.